From Know-How to Grow-How

We are a turnkey indoor vertical farming solutions provider

At Urban Crop Solutions, we combine factory engineering and indoor plant biology to offer end-to-end solutions for Indoor Vertical Farming. It all starts with the crop: your crop and the needs of your market. Based on 5 years of research and real-life trials in our own research center, we help you select the right plant varieties with the right growth recipe for the requirements of your crop.

We design, manufacture, and install automated Plant Factories that can scale to the needs of your business. We help you in your journey to yield and support your first harvest. With us, you’ll be able to grow any crop under LED light anywhere on the planet, year-round. Let us join you in your Journey to profit.

Why a Plant Factory?

HYPER LOCAL

Grow where you sell.

Save food miles and reduce

food waste

NO PESTICIDES

Crops are grown in an enclosed

environment so there is no

need

for pesticides

or herbicides

95% LESS WATER

Water transpired by the crops

is captured and fed back

to the crops

FOOD SECURITY

Available year-round

with consistent quality,

independent of weather

or climate change

ADAPTABLE

Grow crops in different climates,

adapt your crop mix to your

customer’s needs

FRESH AND HEALTHY

Consistent high quality,

taste,

freshness, nutritional

value

and active ingredients

Our Products & Services

Contract Research

We offer you research and ‘grow-how’ in our 10 controlled environment growth chambers, 1 FarmPro and 1 ModuleX for crop cultivar screening, nutrient formulations, plant cultivation techniques, LED light spectrum research, hydroponic irrigation and substrate development. The ‘grow-how’ of our scientists with 30+ years of experience, enables us to serve customers with the support of 200+ recipes.

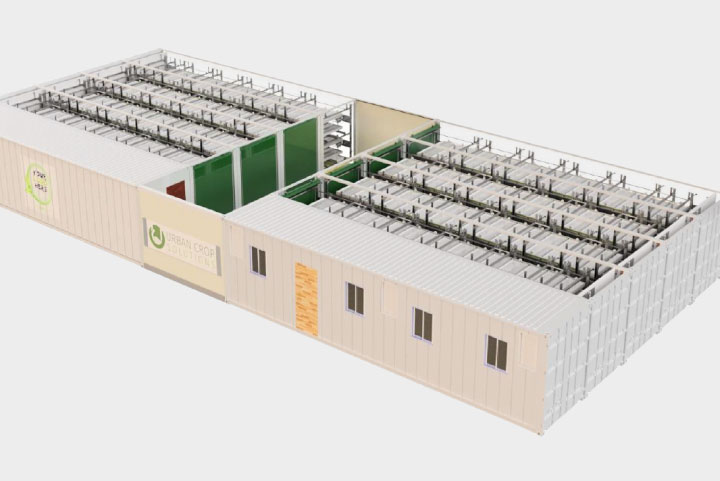

Plant Factories

We supply small to large-scale plant factories that can be installed as standalone systems or within an existing building or warehouse. Growth surfaces and base prices start at 68.6 harvest m2, and 153,000 EUR. Our solutions come with differing levels of automation.

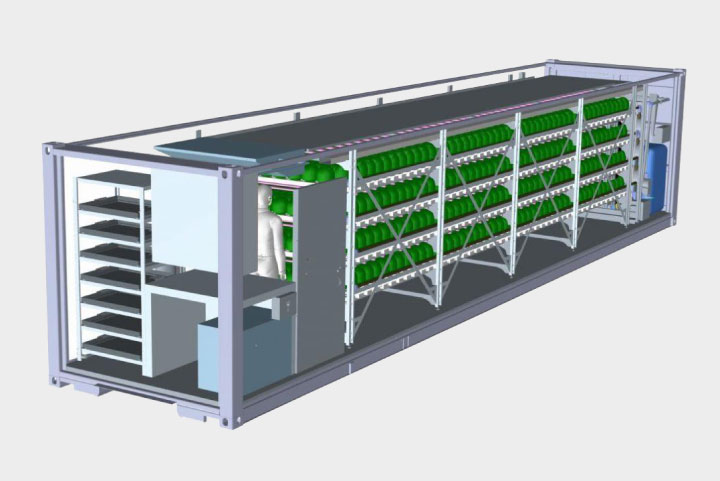

ModuleX Plant Factory

The ModuleX is a 2nd generation plant factory and our most efficient system. It has an integrated BenchCarousel that reduces labour costs. It moreover has an independent climate zone and nutrient system per grow module, allowing for the growth of crops from different climate zones, side by side. And is scalable, allowing you to start-up small, and scale-up fast.

Applications and Industries

Retail

Plant processing

Restaurants

and food service

Plant

based medicine

and nutraceuticals

Universities

and research institutes

Nurseries

and floriculture

Our Projects

IKEA

As part of its sustainability program, a FarmPro has been operating for IKEA’s restaurant division on the parking lot of its store in Malmö, Sweden. They grow fresh, healthy vegetables ‘from farm-to-plate’. Food-miles from the parking lot to the kitchen have been reduced from 2000 km (1243 mi.) down to 50 m (164 ft).

Bread on Mars

A consortium led by Puratos, a global bakery supply company, has set out to research whether people can bake bread on Mars. Dwarf wheat is now grown on lava rock as a substrate. Urban Crop Solutions developed and installed 2 custom FarmLab. research farms at Puratos’ headquarters near Brussels, Belgium.

Banana Nursery

A custom FarmLab research farm is used as a nursery to grow new banana (Musa) cultivars in a controlled environment. After growing to 50 cm (1,6 ft) they are checked for resistance to climate change.

indoor biology science now allows you to grow just about anything. Step by step, more and more crops

become economically viable in indoor farming. It is not a question of if, but when it will break through

in many applications and industries. Above all, the substantial savings in freshwater, land, food waste

and food miles make this a truly sustainable technology. How exciting to be part of this!

— Tom Debusschere, Co-Investor & Board Member